FLAT & FLOAT GLASS

The glass obtained by floating molten glass paste on the liquid tin until it is sufficiently hardened and without adding any dyestuff is called a flat (colorless) glass.

Flat glass can be used as safety and security glass, temperature-controlled glass, sun-controlled glass, noise controlling glass, heat and sun controlling glass and decorative glass by Application of secondary processes such as edge processing, bending, tempering, partial tempering, lamination, coating, double glazing.

Thanks to the features added to the flat glass by secondary operations, area of utilization in many industries such as construction, decoration, automotive, white goods, agriculture, energy are provided.

TEMPERED GLASS

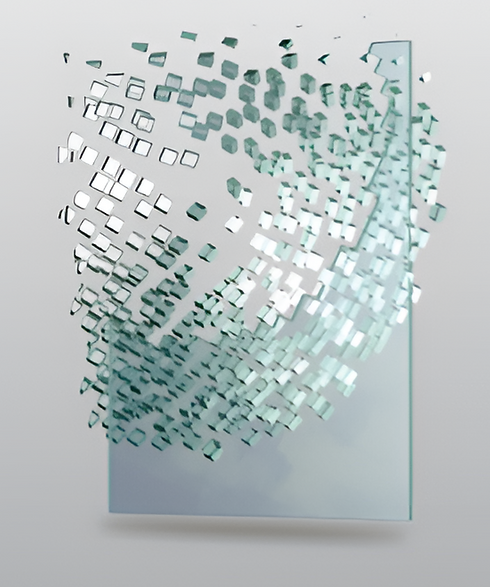

Tempering is the heat treatment of the glass. Tempering is done by heating the glass at 650 – 700°C in a furnace for a sufficient period of time and followed by sudden cooling by compressed air. The surface hardens with reduced temperature. Firstly, the outer surface, then the inner part of the glass cools down, so that on surfaces compressive stress accumulates, while the center has tensile stress. Tempered glasses are approximately 5 times more durable than regular glass. Heat resistance is more than normal glass. It is a Safety Glass class product that does not cause injury to the users due to the small size of the fragments when it’s broken.

Processes such as cutting, edge processing and drilling cannot be performed on tempered glasses. Tempering process does not change the volume, color and chemical structure of the glass.

While the tempered glass can withstand a sudden temperature change of 200 °C (thermal shock), the non-tempered glass can be broken when subjected to thermal shock of about 40 °C.

LAMINATED GLASS

Laminated Glass is produced by bonding two or more glass plates together with the help of heat and pressure after laying PVB sheets or other interlayers between the glass plates.

Laminated glass holds the shattered parts in case of breakage and reduces the risk of injury. Therefore, laminated glass is a safety and security glass. Minimizes the risk of injury to accidents caused by people crashing on glass. Provides security against impacts from outside. It prevents or delays forced entries or Vandal attempts. It contributes to sound insulation. It blocks 97-99% of ultraviolet rays(UV), which are the cause of fading in the colors of furniture and fabrics.

Laminated glass production can be made as clear laminated, colored laminated, bent laminated and acoustic laminated.

All plates are clear float or low iron float glass in clear laminated production.

CURVED GLASS

Curved glass has the same physical and mechanical characteristics of horizontal tempered glass. After heating, the softened glass pane is bent between computer controlled bending jaws in order to form the desired radius followed by sudden cooling by compressed air.

Processes such as cutting, edge processing and drilling cannot be performed on bent&tempered glasses. Only sand blasting for decorative purposses is allowed. Bent glass is used on facades, balustrades, glass doors, furtniture glass, automative glass, etc.

INSULATION GLASS

These are units made by combining two or more glass plate and filling gap between glass plates with gases (argon etc.) that will provide proper dry air or insulation compatible with ambient pressure.

In order to create an air or gas gap between the glass plates, a spacer strip should be used and dehumidifier materials should be put in spacer strips. The glass plates and spacer strips must be joined using internal insulating material (butyl / polyisobutylene) and external insulating material must be applied to seal the insulating glass.

BULLETPROOF GLASS

GLASSEXPORTER partners produce bullet proof glasses under EN1063 standarts.

Bullet-proof glasses protects individuals against firearm attacks: Generally a multilaminated assembly,contains thinner polycarbonate against non splitting of glass cracks.If it is required,layers of multilaminated assembly can be used tempered.The various classes according to EN1063 are determined by the type of weapon and immunition.

CUSTOM DESIGN GLASS

When you have your own project, contact GLASSEXPORTER to get information about the production feasibility and estimated costs.

Our technical team will check all the possibilities within the machine park GLASSEXPORTER has, and commercial team will inform you about all the processes and prices.

SLIDING DOOR SYSTEMS

Photocell Sliding Doors both increases the comfort of your places and enable you to decrease energy costs.

Applications

GLASSEXPORTER specializes in designing and creating custom glass solutions for both commercial and residential applications. With an emphasis on high-quality and attention to detail, we offer a wide range of products that include office divisions, glass doors and partitions to perfectly fit your space. Let us create the perfect glass solution for you and see how details make the perfection

Our Products

World Class Standards

GLASSEXPORTER is committed to providing a variety of quality merchandise for customers. By using the latest technologies and applying strict quality control procedures, we’ve become known for having the best products in the industry. Take a look at what we currently have in stock, and get in touch to order or learn more.